UV curing or UV-A (320-400 nanometers) is a fast, efficient, and environmentally friendly process that requires no solvents or heat. The UV curing process reduces energy consumption, cuts costs, and eliminates harmful emissions.

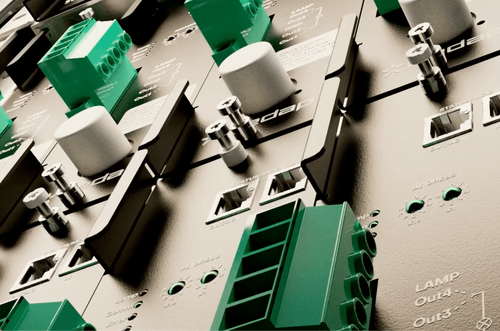

Nedap’s industry-leading UV lamp driver technology enables you to:

Low-pressure UV solutions are used for curing coatings and adhesives on heat-sensitive substrates. They produce lower intensity UV radiation and generate less heat. They can also cure materials that require specific UV wavelengths.

Nedap supplied the lamp drivers to one of the major companies in the printing industry in the USA. The company wanted to change the power supply to more intelligent Electronic Lamp Drivers.

Discover cases for this application

Read our blog and stay up to date.